General Coffee Machine Checkup

Prevention is better than cure

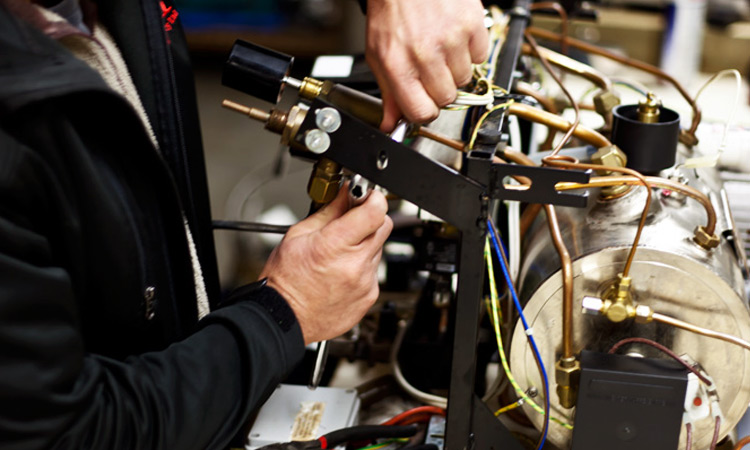

Regular maintenance checkups are the heartbeat of any well-functioning coffee machine. At Refix, we take pride in offering comprehensive services to ensure your coffee equipment stays in prime condition. Our thorough inspection process begins with a meticulous examination of all components, from the grinder to the brewing unit. We assess for any signs of wear and tear, potential leaks, or irregularities in performance.

Why are these checkups crucial? First and foremost, they prevent small issues from snowballing into major malfunctions. By catching and addressing minor problems early on, we save you both time and money in the long run. Additionally, routine maintenance ensures optimal performance and extends the lifespan of your coffee machine. You'll enjoy consistent, high-quality brews, maintaining customer satisfaction and enhancing your reputation.

Regular checkups also uphold hygiene and sanitation standards. Coffee machines can harbor bacteria and mold if not cleaned and maintained properly. Our technicians not only inspect for mechanical issues but also clean and sanitize the internal components thoroughly. This not only enhances the taste and quality of your coffee but also ensures compliance with health and safety regulations.

Ultimately, investing in regular checkups for your coffee machine is a proactive approach to preserving your business's productivity and reputation. With Refix, you can rest assured that your equipment is in expert hands, allowing you to focus on serving up the perfect cup of coffee every time.

Here are reasons why to do checkup periodically :

1. Enhanced Dependability: Implementing routine machine inspections enables proactive identification and resolution of potential equipment issues, minimizing breakdowns and reducing unplanned downtime, thus enhancing equipment reliability metrics.

2. Improved Output Consistency: Regular inspection and maintenance ensure equipment operates at optimal levels consistently, resulting in enhanced product quality, reduced part defects and rejects, and decreased rework and material wastage.

3. Prolonged Equipment Lifespan: Adhering to a planned inspection and maintenance regimen mitigates breakdowns and damage due to maintenance neglect, thereby extending the service life of equipment and ensuring sustained operational efficiency.

4. Enhanced Employee Safety: Regular equipment health assessments mitigate safety risks posed by unnoticed maintenance requirements or equipment malfunctions, promoting a safer working environment for equipment operators and facility personnel.

Call us now and make sure you save time and money before your machine breaks down

0097128867525